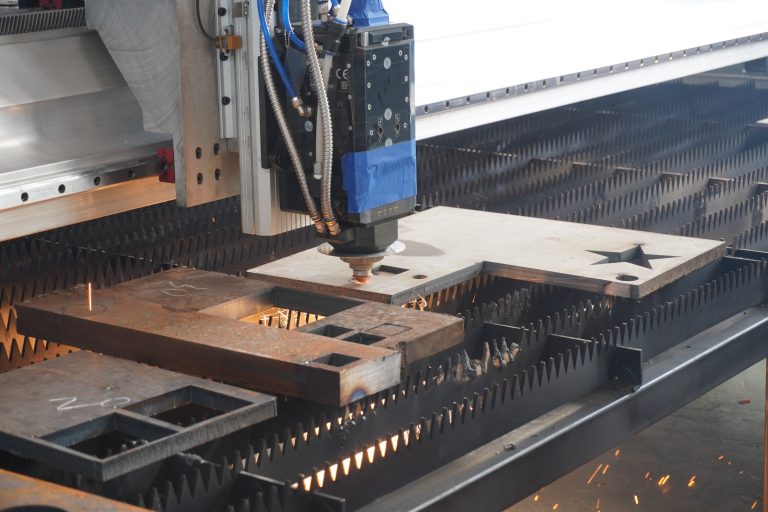

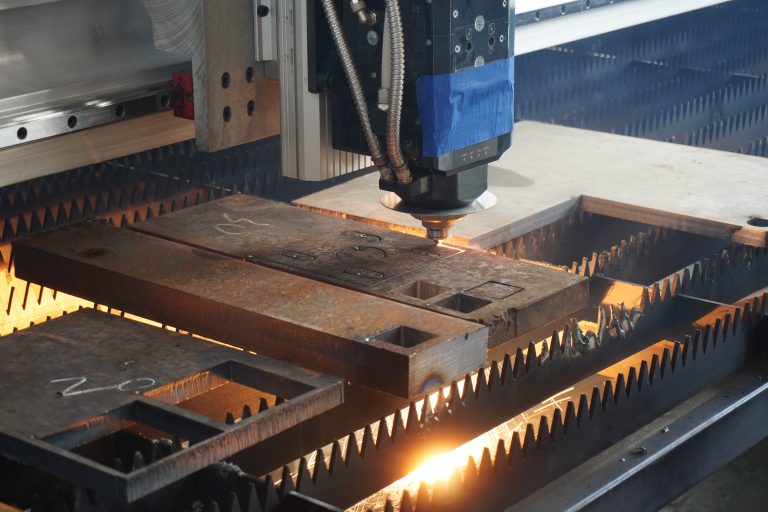

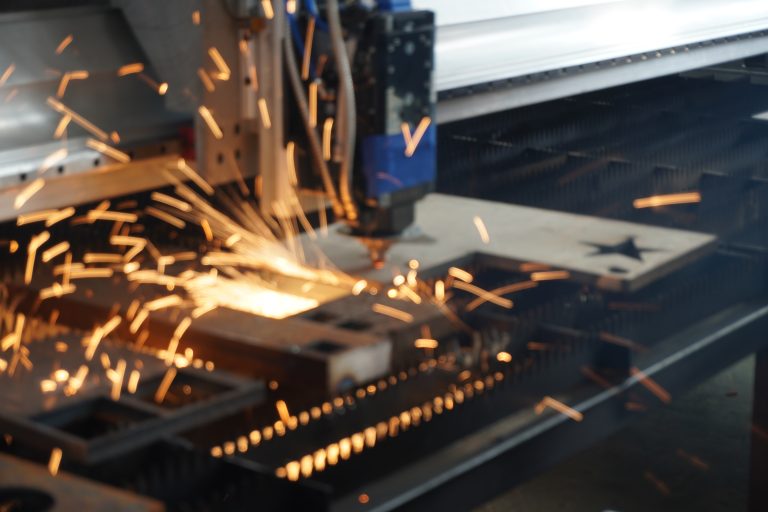

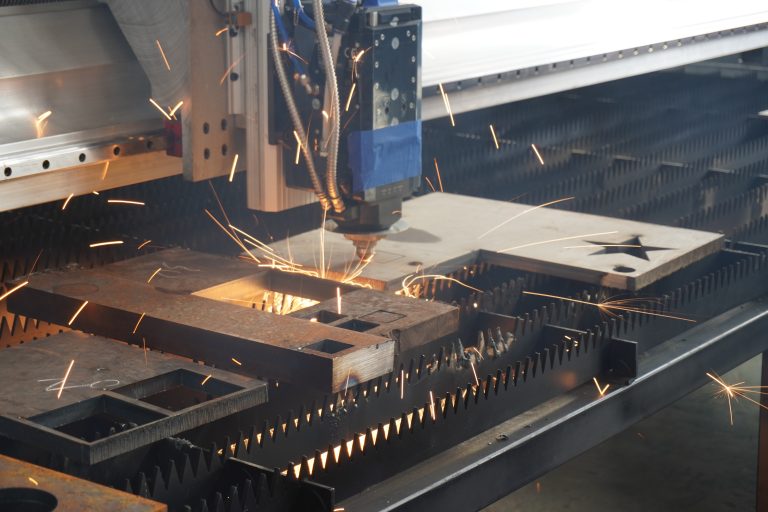

As a laser cutting practitioners, it is necessary to have a comprehensive understanding of the laser cutting machine, especially in the cutting process, a deeper understanding of the cutting process, in order to enhance their own operating technology. Today, share with you some laser cutting knowledge, I hope to help you in the cutting process.

Focus control

Stainless steel class: (focus for negative focus) (the amount of out-of-focus adjusted according to the thickness of the plate)

①: the higher the focus the brighter the cutting surface.

②: The hard slag hanging on the lower surface is: the focus is too high, the speed is too slow, and the air pressure is too small.

③: The lower the focus, the rougher the cutting surface.

④: The soft slag on the lower surface is: the focus is too low, the speed is too fast, the air pressure is too large, and the power is too high.

⑤: The cut is impervious to: the focus is not right, the power is too low, the speed is too fast.

Carbon steel: (focus is positive focus) (the amount of focus is adjusted according to the thickness of the plate)

The hard slag hanging on the lower surface is:

①: the focus is too low;

②: the air pressure is too slow;

③: the power is too small;

④: the speed is too fast.

The roughness of the cutting surface is:

①: the focus is too up;

②: too much air pressure;

③: too much power;

④: material problem.

Cutting nozzles and lenses

1.Selection of Nozzle and Lens for Cutting Carbon Steel: (CO2)

①: Selection of Lens:

For cutting 1-8mm carbon steel, use a (5-inch) lens.

Cutting 8-10mm of carbon steel to use (7.5 inches) of the lens.

②: Selection of nozzle:

For cutting carbon steel of 1-6mm, use a nozzle (Φ1.0 double).

For cutting carbon steel of 8-10mm, use a nozzle (Φ2.0).

2.Selection of nozzle and lens for cutting stainless steel: (CO2)

①: Selection of lens:

For cutting stainless steel of 1-4mm, use a (5-inch) lens.

When cutting 4-6mm stainless steel, use a 7.5-inch lens.

②: Selection of nozzle:

For cutting 1-3mm stainless steel, use a nozzle (Φ1.5). Cutting (Nitrogen pressure) 10kg-13kg

Use (Φ2.0) nozzle for cutting 3-4mm stainless steel. Cutting (Nitrogen pressure) 13㎏-15㎏

For cutting 5-6mm stainless steel, use (Φ2.5) nozzle. For cutting (Nitrogen pressure) 14㎏-16㎏.

Selection of Auxiliary Gases

Air: ①: Used as cutting gas ②: Used for cooling the cutting head ③: Used for dust removal inside the optical path (to protect the lens and prolong the use of the lens)

Oxygen: Used as a gas for cutting carbon steel (combustion-assisted) Purity 99.5%

Nitrogen: Used as a gas for cutting stainless steel (cooling) Purity 99.9% (Cutting speed of carbon steel is 3/4)

High-purity Nitrogen: Used as a gas for laser cutting 99.999% Purity High-purity nitrogen: as a laser gas 99.999% pure

High-purity helium: as a laser gas 99.999% pure

High-purity carbon dioxide: as a laser gas 99.999% pure

Laser Hole Cutting Requirements

① Cutting of carbon steel plate within 8㎜, the hole diameter should not be smaller than the thickness of the plate, and cutting of plate within 10㎜, the hole diameter should not be smaller than 1.2 times of the thickness of the plate.

② Cutting stainless steel plate within 4㎜, the hole diameter can not be smaller than the thickness of the plate, cutting 4㎜ or more plate, the hole diameter can not be smaller than 1.2 times the thickness of the plate.

③ If the hole diameter exceeds the above range, use pulse cutting or marking treatment.

Pulse cutting requirements

① Speed is 30-50% of continuous wave.

② The power should be larger compared with continuous wave.

③ The air pressure is about two times greater than that of continuous wave. Continuous wave is used for perforation.

Selection of perforation method

For carbon steel material

① Normal perforation: For cutting carbon steel less than 5㎜.

② Progressive piercing: For cutting carbon steel of 6-8㎜. (The corresponding parameter P990012 must be modified.)

③ Powerful perforation: Applicable for cutting carbon steel of 10-12㎜ (violent perforation method).

The perforation height is not lower than the cutting height; the perforation air pressure is not lower than 1.0 .

Reference of the introduction line

Applicable for cutting stainless steel

① Single (small circle cutting or deceleration) method is used for cutting stainless steel of 1-3㎜.

②Two types of cutting (small circle cutting or deceleration) are used for cutting stainless steel of 3-6㎜.

③The air pressure for cutting is 1.5 times larger than the air pressure for cutting.

Reason analysis of violent hole

① Insufficient piercing time

② Excessive air pressure

③ Incorrect focus

④ Too low piercing height

⑤ Inconsistent pulse frequency

⑥ Excessive power

Today, we will first share these laser cutting tips with you in the hope that they will help you in the cutting process.