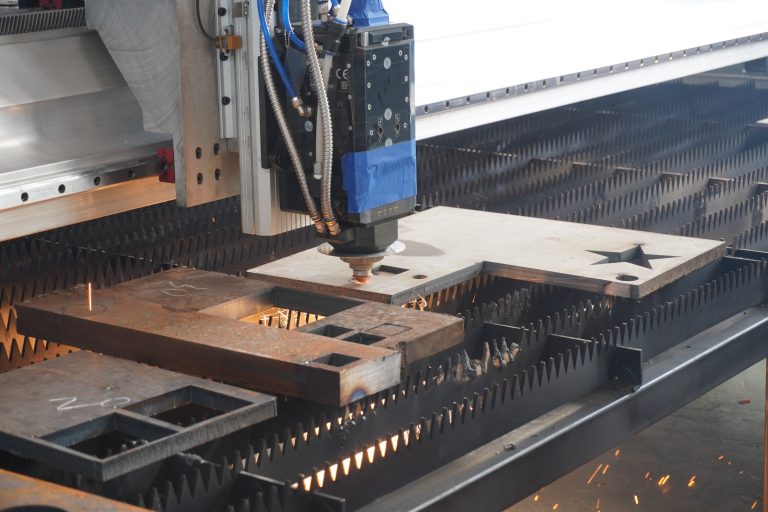

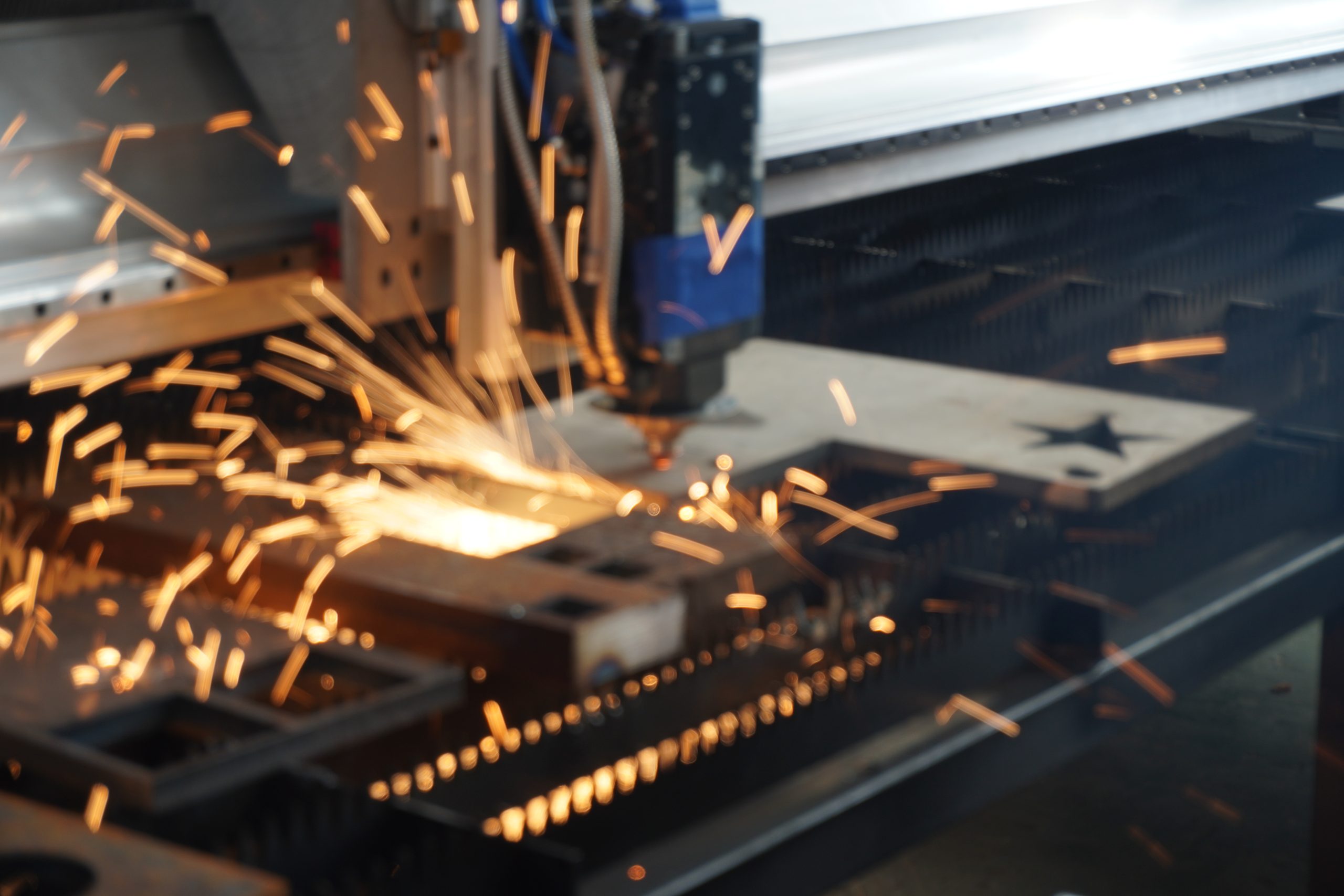

1. the basic principle of laser cutting pipe

First, let’s understand the basic principle of laser cutting tubing. Laser cutting is a high-precision, high-speed cutting method that uses a high-energy laser beam to irradiate the surface of the pipe, causing the material to rapidly melt and vaporize.

2.Common problems and solutions

①Tube cutting is not uniform

Problem description: In the laser cutting process, the cutting surface of the tube is not smooth and obvious cutting marks appear.

Solution: Adjust the focal length and power of the laser beam to ensure that the focus position is accurate, while reducing the cutting speed and increasing the pressure degree of the auxiliary gas.

②Tube wall burning through, deformation

Problem description: During the cutting process, the tube wall is burned through, producing holes or deformation.

Solution: Appropriately increase the cooling water flow of the cutting head, while adjusting the focal length and power to avoid heat concentration.

③Cutting edge burr

Description of the problem: Burrs appear on the cutting edge, affecting the quality of the pipe.

Solution: Keep the cutting head clean and perform regular maintenance. At the same time, the surface of the pipe can be pre-treated before cutting, such as polishing, descaling and so on.

④Cutting section tilt

Description of the problem: The pipe cutting section is tilted, affecting the subsequent use.

Solution: Adjust the position and angle of the cutting head to ensure that it is perpendicular to the surface of the pipe.

⑤excessive output power

Excessive laser output power is a common problem in the laser cutting process. Excessive power may lead to excessive thermalization of the material or even burning, thus affecting the cutting quality and accuracy. At the same time, this may also cause damage to the nozzle of the cutting head, further affecting the cutting effect.

⑥improper nozzle selection

In addition to excessive laser output power, improper selection of cutting head nozzles is also a common problem in the laser cutting process. Different nozzles are suitable for different materials and cutting needs. If an inappropriate nozzle is selected, it may affect the cutting speed, edge quality and material stability.

If you are still worried about choosing the right nozzle, you can contact us at any time. With our professional technical team and rich experience, we will provide you with suitable nozzle selection suggestions for your reference.

This is the content of the common problems of laser cutting tubes for you today, I hope this article can provide you with some help in the process of laser cutting tubes.