In the field of glass fabrication, traditional mechanical drilling methods are no longer able to meet the high standards required by modern industry due to their slow processing speed, poor precision and potential damage to the environment. However, as technology advances, glass laser drilling machines are becoming the preferred equipment in the glass fabrication industry due to their superior performance and unique benefits.

In the field of glass manufacturing, traditional mechanical drilling methods have become increasingly unable to meet the high standards required by modern industry due to their slow processing speed, poor precision and potential damage to the environment. However, glass laser drilling machines, with their advanced performance and unique advantages, are becoming the preferred choice for glass manufacturing. These machines are used in various industries, including flat glass, household glass, glassware and optical glass, to name a few. They are equipped with advanced laser drilling tools that offer the advantages of high processing speed, precision and flexibility. In comparison to traditional mechanical drilling, glass laser drilling not only significantly increases processing efficiency but also ensures the accuracy and quality of each hole, meeting the high demands of modern industry for glass products.

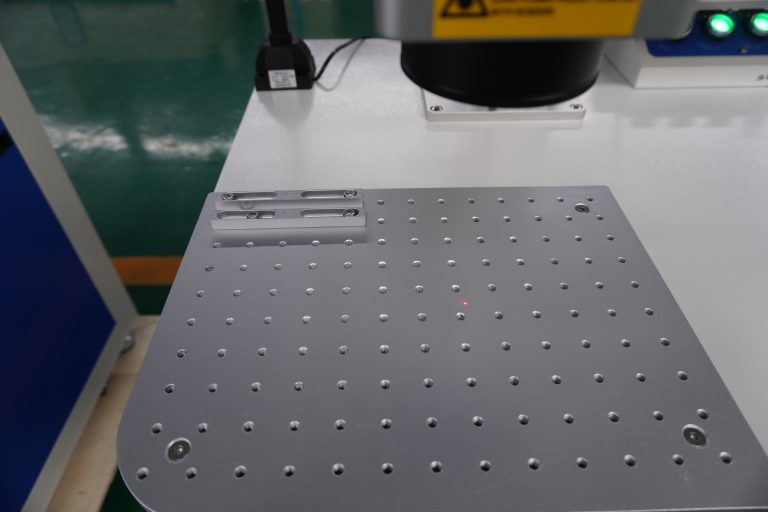

The glass laser hole-punching machine is a versatile tool that can be used in various industries, such as glass panels, household appliances, glassware and optoelectronics. It uses a state-of-the-art laser hole-punching system that is both fast and precise, allowing it to meet the high demands of modern industry. The machine can be used for different types of holes, such as round, waist-shaped, square and special shapes, and its accuracy and stability make it a highly suitable choice. This adaptable system allows the machine to work well with a wide range of glass products, meeting the needs of customers.

In addition, the laser hole drilling machine boasts a number of significant advantages in terms of environmental protection and energy efficiency. Its waterless processing capabilities not only safeguard the environment, but also ensure the surface of the glass products is more clean and free from any contamination, thereby reducing the subsequent processing time and costs. Furthermore, the machine’s minimal damage to the glass ensures a higher level of precision and durability in the final products.

In terms of processing speed, the glass laser hole drilling machine is also outstanding. Its processing speed is 5 to 10 times that of traditional CNC machines, meaning it can complete more tasks in the same amount of time, creating greater value for customers. This advanced and precise processing method is undoubtedly a revolutionary change for the glass processing industry.

In terms of processing speed, the glass laser hole drilling machine is unparalleled. Its processing speed is five to ten times that of traditional CNC machines. This means that within the same time frame, the laser hole drilling machine can complete more tasks, offering greater value to customers. This highly precise and efficient processing method is undoubtedly a revolutionary change for the glass processing industry.

To summarise, the glass laser hole drilling machine is becoming the industry’s leading product due to its excellent performance, flexible processing methods, environmental friendliness and high processing speed. If you are looking for a highly precise and environmentally friendly glass processing method, the glass laser hole drilling machine is an excellent choice. Let’s work together to meet the future challenges of the glass processing industry.