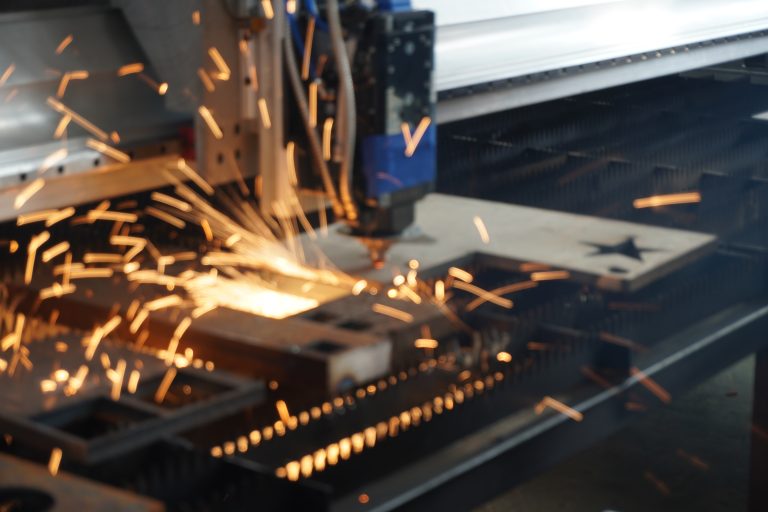

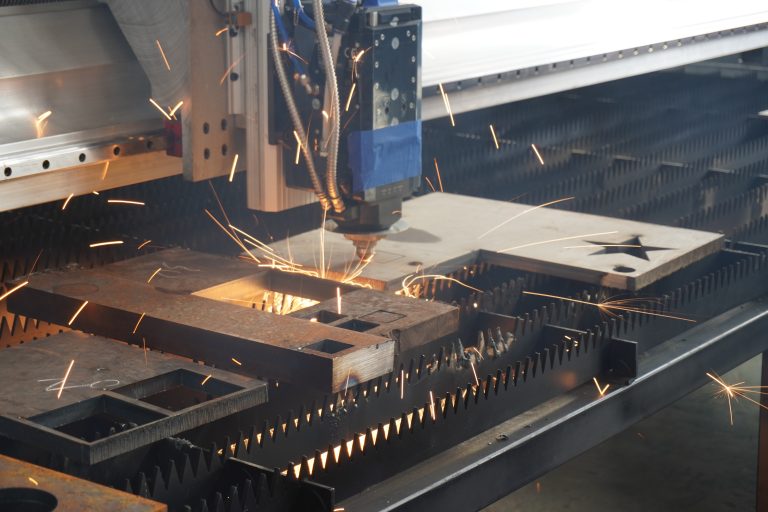

Laser cutting is the use of high power density laser beam scanning over the surface of the material, in a very short period of time the material will be heated to thousands to tens of thousands of degrees Celsius, so that the material melting or gasification, and then high-pressure gas will be melted or gasification of the material from the slit blowing away, to achieve the purpose of cutting the material.

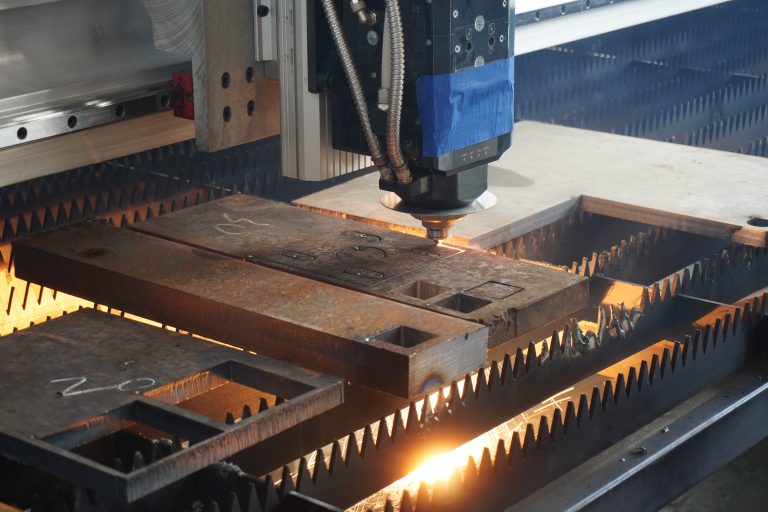

Three-dimensional laser cutting mechanism relative to two-dimensional laser cutting, three-dimensional laser cutting need to constantly adjust the laser cutting head posture to ensure that the laser cutting head is always perpendicular to the surface of the workpiece, so as to obtain excellent cutting quality. In actual production, three-dimensional laser cutting programming needs to first three-dimensional modeling of the parts, and then imported into the three-dimensional programming system to generate paths, and need to be manually adjusted according to the characteristics of the parts, the characteristics of the workpiece, in order to avoid collision of the cutting head, the operation of the complexity of the workload is large. As the cutting head of 3D laser cutting machine is equipped with capacitive sensors, it can automatically adapt to the shape of the part and always keep a certain distance from the part for cutting, therefore, in the case where the surface of the part does not change drastically, only the 2D programming system of 3D laser cutting machine can meet the production needs.

Applications of 3D laser cutting

Three-dimensional laser cutting is widely used in sheet metal processing, metal processing, advertising production, kitchenware, automotive, lamps, saw blades, lift elevators, metal crafts, textile machinery, food machinery, glasses production, aerospace, medical equipment, instruments and other industries. Especially in the sheet metal processing industry has replaced the traditional processing methods, favored by industry users.

Materials that can be processed: stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminum zinc-plated plate, pickled plate, copper, silver, gold, titanium, and other metal plates and tubes cutting.

Advantages and disadvantages of 3D laser cutting

It has been proved by production practice that three-dimensional laser cutting has the following advantages:

① Good flexibility, can adapt to the cutting and processing of workpieces of different shapes.

② high precision, can meet the aluminum alloy rolling stock, stainless steel subway and other products manufacturing precision.

③ high economic efficiency, can replace the traditional manufacturing process of trimming die and punching die, its process steps are simple, short manufacturing cycle, fast cutting speed, small width of the slit, high processing quality, can significantly reduce costs, shorten the development cycle of the new model, has a good economic value and application prospects.

Three-dimensional laser cutting development trend

- Along with the development of lasers to high power and the use of high-performance CNC and servo systems, the use of high-power laser cutting can be obtained at high processing speeds, while reducing the heat-affected zone and thermal aberration; the ability to cut the thickness of the material plate is also further improved.

- According to the influence of laser cutting process parameters, improve the processing technology.

- Laser cutting will be highly automated, intelligent direction. CAD / CAPP / CAM [4] and artificial intelligence used in laser cutting, the development of highly automated multi-functional laser processing system.

- To the development of multi-functional laser processing center, laser cutting, laser welding and heat treatment and other processes after the quality of feedback integrated together to give full play to the overall advantages of laser processing.

- With the development of Internet and WEB technology, the establishment of WEB-based network database, the use of fuzzy inference mechanism and artificial neural network to automatically determine the laser cutting process parameters, and can be accessed remotely and off-site control of the laser cutting process has become an inevitable trend.

- Three-dimensional high-precision large-scale CNC laser cutting machine and its cutting process technology, in order to meet the needs of automobile and aviation and other industries of three-dimensional workpiece cutting, three-dimensional laser cutting machine is to high efficiency, high precision, multi-functional and highly adaptable to the direction of development.

The 3D laser cutting machine is mainly used in automobile manufacturing, machinery manufacturing, metal processing and other production enterprises that have processing needs for 3D workpieces. It is highly intelligent, which can effectively save labor cost, material cost and time cost. In the production and processing, it does not need to repeatedly adjust the angle manually, and the intelligent setting of the system enables it to carry out the cutting work on any face of the workpiece. It takes the robot as the main body and is controlled by the system, which runs very flexibly and quickly with very stable performance. Moreover, users can install the robot in different forms according to their own needs, such as positive or inverted, etc., in order to ensure accurate cutting of different shapes The principle of 3D laser cutting machine is actually similar to that of the fiber laser cutting machine, both of which emit laser light through the fiber laser generator, and then transmit it through the fiber optic to the cutting head, and then through the control of the system to come in the characteristics of the high stability and high degree of the majority of manufacturers to make the Benefits doubled.