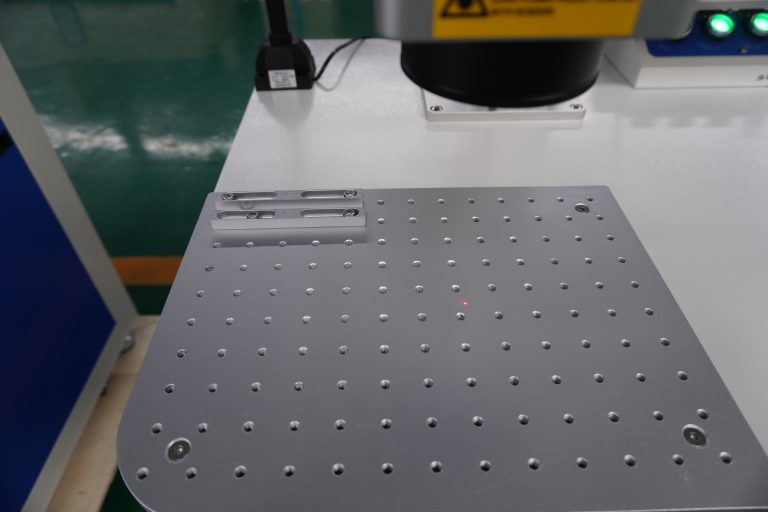

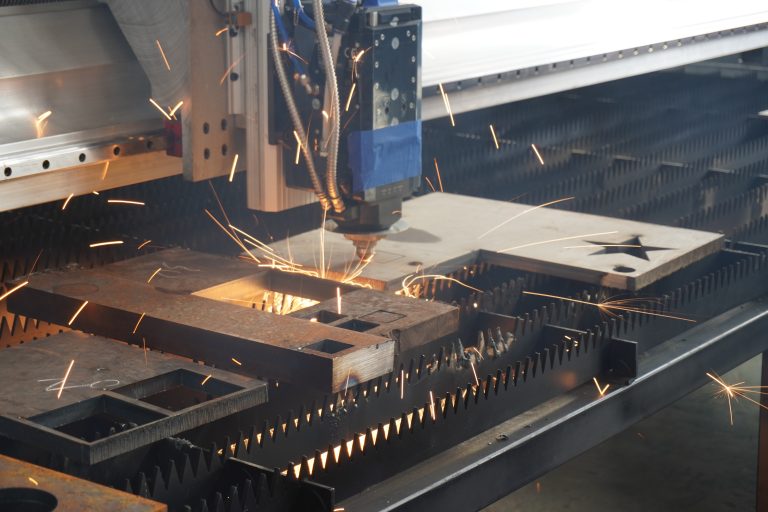

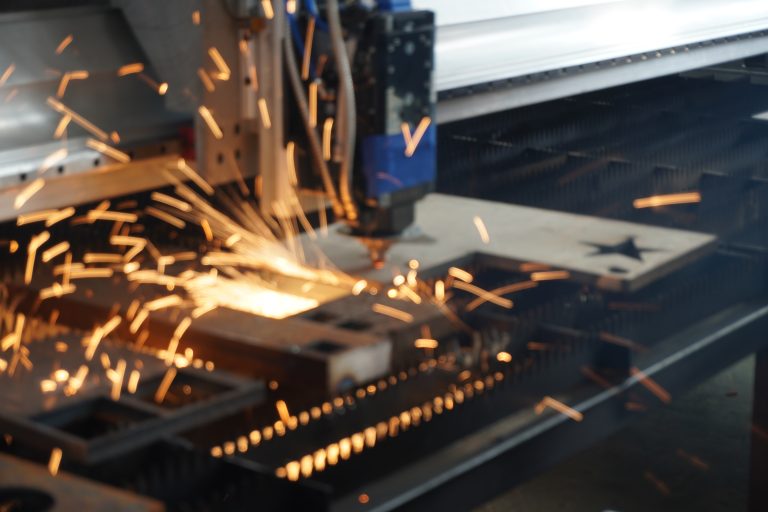

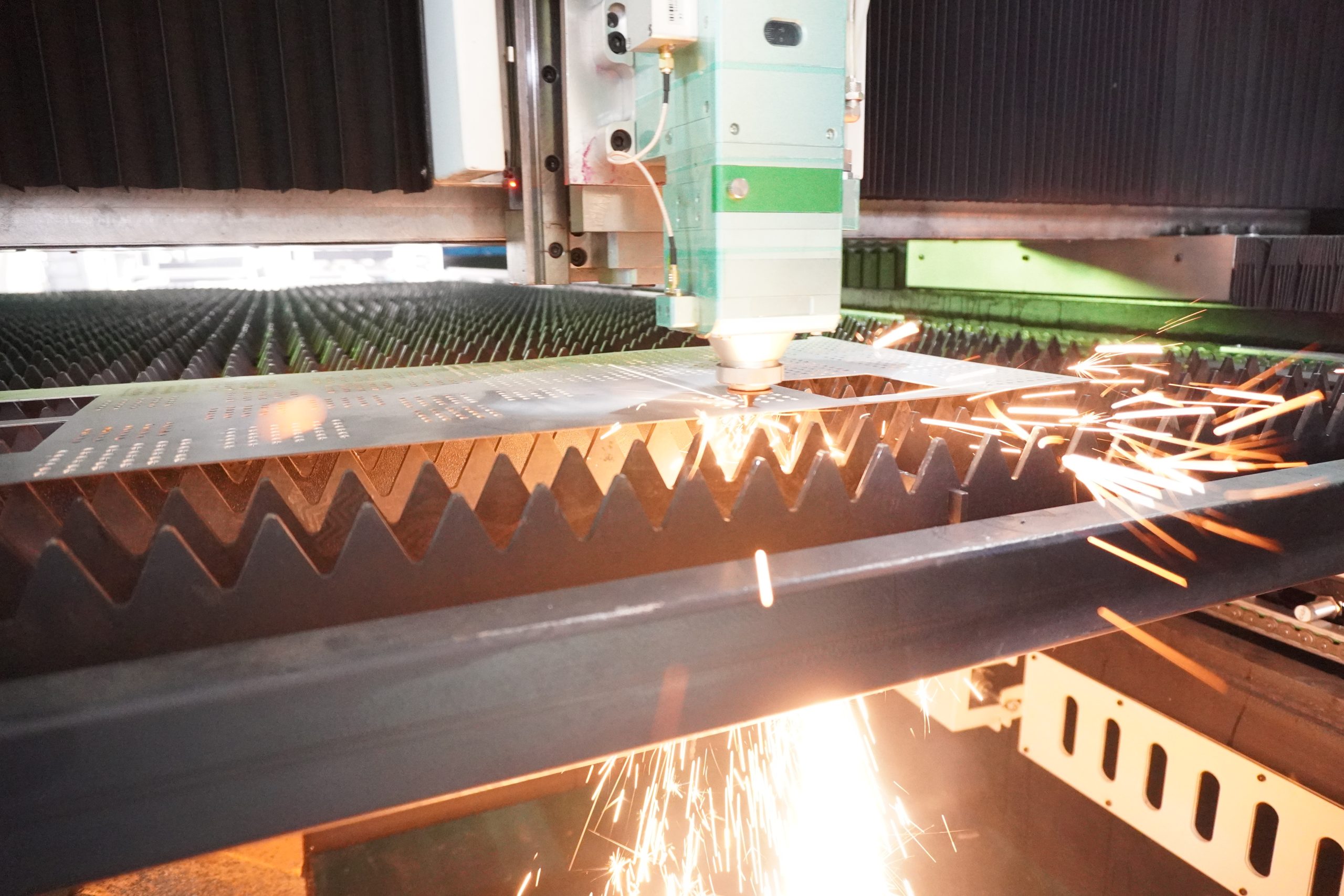

Laser cutting technology is widely used in modern manufacturing industries, where condensation on the laser cutting head is particularly common. Condensation phenomenon not only affects the cutting quality, but also may damage the equipment and increase maintenance costs. This article will discuss the hazards of laser cutting head condensation and its solution.

The dangers of laser cutting head condensation

1.Damage to Optical Elements:

Condensation can form a film or droplets of water on the surface of optical elements (e.g., focusing and collimating mirrors), damaging their optical performance.

Prolonged exposure to water vapor may result in corrosion of the optical elements, growth of bacteria, or damage to the coating layer, reducing its service life.

2.Reduced Cutting Quality:

Water vapor can affect the transmission and focusing of the laser beam, resulting in unstable cutting quality and possible uneven cutting edges, wider slits, or opaque cuts during the cutting process.

3.Equipment Malfunctions and Downtime:

Moisture infiltration into the laser cutting head’s internal electrical components and control system can cause short circuits or equipment downtime malfunctions, affecting productivity and increasing production costs.

Solutions to laser cutting head condensation

1.Keep the cutting environment dry:

Use dehumidifiers or air conditioners to control the humidity in the shop, keeping it within a reasonable range (usually between 40% and 60%), and avoiding operating the equipment in high humidity environments, especially in the morning or on rainy days.

2.Use dry air:

Ensure that the air source for the laser cutter is dry. If compressed air is used, make sure that the air has been dried, and check and replace the air filter and drying equipment regularly to ensure that they work properly.

3.Check the cooling system:

Ensure that the cooling system is working properly, to avoid the cooling water temperature is too low, you can appropriately adjust the temperature of the high temperature water of the chiller [set 28 ℃ in summer], and check the cooling pipeline whether there is a leakage phenomenon, timely repairs and processing.

By taking the above measures, the condensation problem of the laser cutting head can be effectively reduced or avoided to ensure the normal operation of the equipment and cutting quality.

If the problem persists, it is recommended to contact the equipment supplier or professional technicians for in-depth inspection and treatment.

I hope this article can help you solve the problem of laser cutting head condensation and improve the operating efficiency and cutting quality of the equipment.